A, the choice of battery cells

1,3.2 V lithium iron phosphate,3.7 V ternary lithium battery, this is a simple distinction.

2, the battery cell is divided into numerous grades, there are capacity, power models to distinguish. The difference involved is the discharge rate, theoretically the advanced the discharge rate the better, but the power battery also has high and low distinction.

3, in terms of operation, the little people retail purchase, isn't to buy a good battery. Good batteries are given precedence to supply electric vehicles, and the screened down bones can flow into the request, and the request will be screened again by large merchandisers, with the good bones used for battery packs and the poor bones entering the retail request. Note anyhow of the brand, the bones that enter the retail request won't be too good, indeed if they're first- line brands. Of course, the advanced the decoration you pay, it doesn't count that you can get good goods.

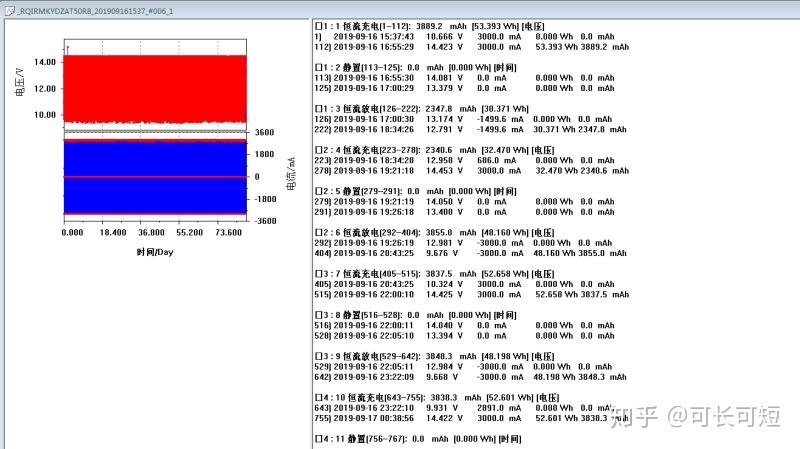

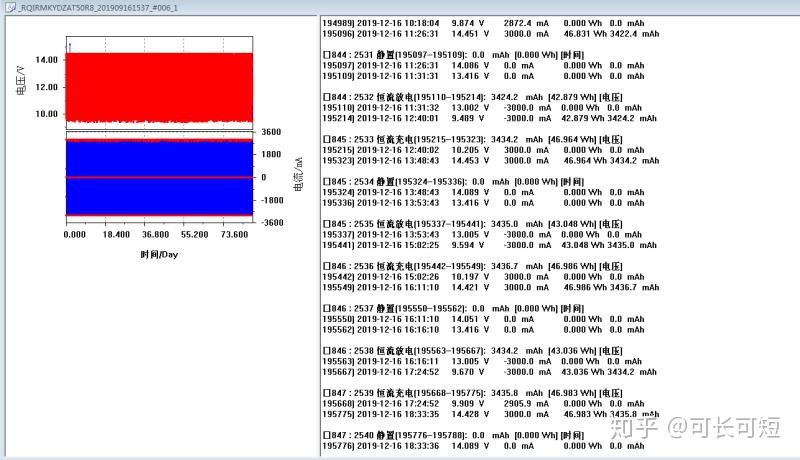

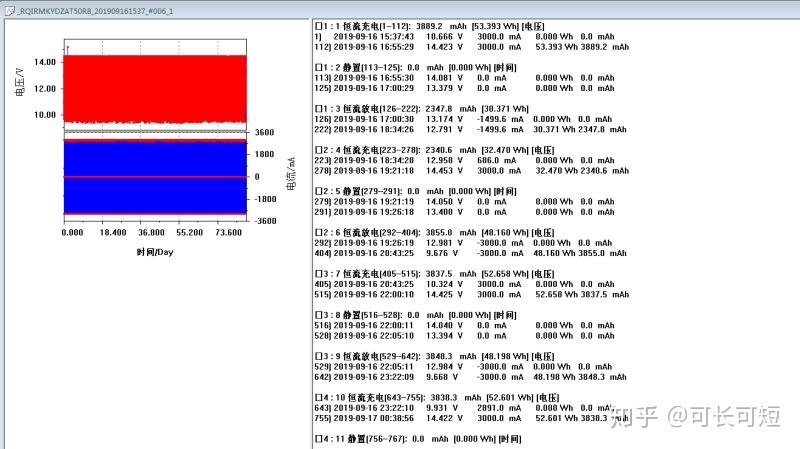

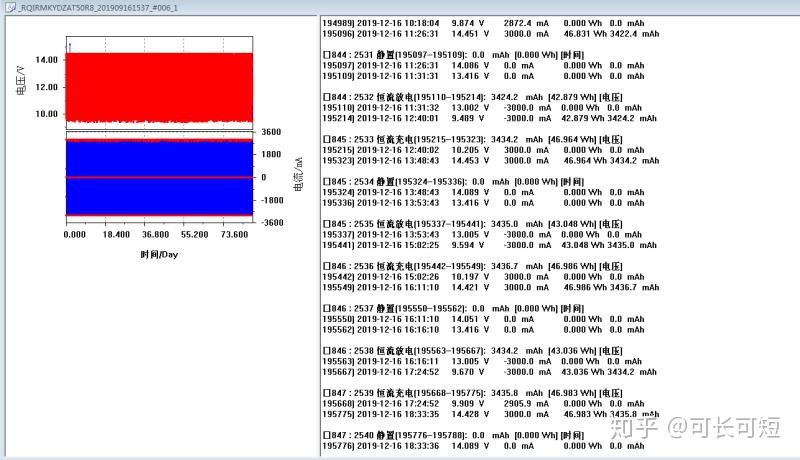

4, the battery webbing problem, how to distinguish between good and bad after the battery cells arrive. Must use internal resistance tester, powertest.However, the worse the quality, If the difference between the nominal parameters is bigger. The lower the internal resistance of the battery, the better, as a rule, is below 50. 50 above may be old batteries, poor batteries.

5, cycle life problem, this is a big problem. numerous musketeers assembled themselves, the capacity isn't over to standard, with a period of time to drop power obviously. This is the maturity of the core problem, retail guests are delicate to bypass this hole, after all, there's no channel to get good goods as well as no outfit to check the quality of the battery cells.

Alternate, the core processing problem we now get the core, and not that the appearance of the immediate processing. To its processing again in order to use.

Battery pack assembly must be added to match the protection plate!

Batteries bear corresponding thickness, the further harmonious the better and furtherstable.However, there will be inadequate capacity, performing in serious battery protection plate discovery failure, If the match isn't harmonious. How to deal with it?

1, if there are conditions, on the machine webbing, no machine on the internal resistance tester 1 1 test, voltage, internal resistance, capacity harmonious put together, resting for a period( 7

15 days), after resting, and also measured, if still harmonious, you can reuse. This is also a physical system to judge the stability of the core.

2, numerous musketeers will also say, why so important trouble, can't be directly assembled and used? Of course you can use it directly, but in case of mismatch, the battery pack will misbehave with the barrel proposition, with the capacity limited at the smallest one. The worst cell in the pack is the upper limit, which in nonprofessional's terms means that the capacity of the pack will drop by 10 to 40. In more serious cases, 1 bad battery in the pack will beget the whole pack to not work. examination and form work is more tedious.

3, the battery spot welding problem

1, battery pack processing and assembly precedence to machine processing is the main, not recommended homemade assembly.

2, why not recommend homemade spot welding? Battery spot welding strength control isn't good, the battery point through the leakage of liquid, nickel distance point isn't solid false welding. Homemade soldering iron welding, solder temperature is too high will hurt the pole piece, it's recommended that low temperature soldering.

3, the thicker the core connection line, the better. The thicker the nickel distance, the better.

4, the battery as a charge and discharge volume vessel, energy conversion will also release heat,non-standard processing may lead to battery pack problems, battery pack processing must be conservative and careful, numerous assiduity labor force suffered numerous losses, that time no battery PACK manufacturers on fire.

4, the battery pack using environmental issues.

1, the battery pack requires leakproof! Short circuit fire probability!

2, the battery pack requires shockproof! Electric vehicles in use, can't be used as out- road vehicles! Nor can you use the external skin of the battery pack to achieve bumper collision, distortion will all beget a short circuit! Try to use the tulle type bumper external box such a way. No caff type, the battery pack in the long times of exertion under the extrusion will lead to the nickel distance out!

3, the battery pack has the conditions to give thermal conductivity channel, energy conversion, timely thermal conductivity can achieve the optimization of the battery. Steel external case addict help, are conventional results. preliminarily, I proposed the power force tenacious package is also a result, is the late conservation trouble.

4,anti-corrosion problem, the battery put a long time rust, there are conditions to try to doanti-corrosion measures.

Five, lithium battery protection board selection

1, electric two- wheeled 40A or lower is enough, three bus above 80A or further. Specifically according to their own motor power to judge the choice.

2, voltage to match, 60V more conventional, to distinguish between ternary, lithium iron, but also to distinguish the number of strings.

3, try to large capacity small power with, stable anddurable.However, be sure to calculate the discharge rate is supported, If the high- power small battery.

4, the conditions as far as possible to choose the protection plate protection voltage is low, giving the battery a certain quantum of fat. For illustration4.25 V protection isn't as good as4.2 V

5, because it'll not give the battery to 100 power, not to go to the posting limit. But utmost of the protection board design aren't paying attention to this point, a many manufacturers have in doing.

6, bowl selection

1, according to the protection plate protection voltage to match, how numerous strings of lithium iron/ lithium ternary

2, according to the total capacity to choose the applicable number of A/ H bowl. Now the request recommended 8A/ H conventional.

3, the bowl should also pay attention to the protection of leakproof, shock- evidence, every day don't watch for the bad fast.

7, electric auto boscage package try to choose a double slice boscage electric auto, lithium battery discharge rate is high, fast acceleration, no good thickets, prone to accidents.

8, the summary of their own assembly battery pack, I suppose, for learning interest for their own use are supported, but for marketable use, we must consider a series of problems similar as after- deals, don't support the use of traditional homemade spot welding to do electric auto battery pack. At the same time, the battery cycle life is also a point that people ignore, which is also the biggest distinction in the request now mixed. numerous of the battery packs that you make yourself, the capacity isn't over to standard, with a period of time to drop the power presto, are common problems encountered in their own assembly.

401,Building A1,No.168,Changshan IndustrialZone Liulian Community,Pingdi Street,Shenzhen Guangdong Province,China

401,Building A1,No.168,Changshan IndustrialZone Liulian Community,Pingdi Street,Shenzhen Guangdong Province,China