- HOME

-

PRODUCT

-

21700 lithium battery

-

26650 lithium battery

-

14500 lithium battery

-

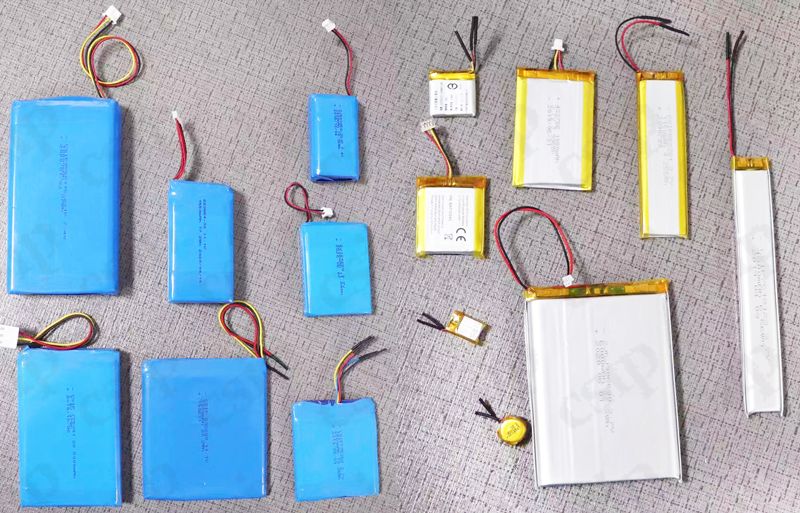

Standard lithium polymer battery

-

Cylindrical lithium ion battery

-

Electronic cigarette lithium battery

-

18650 lithium battery

-

lithium battery pack

-

High temperature lithium polymer battery

-

Low temperature lithium polymer battery

-

High voltage fast charging lithium battery

-

Ultra-thin lithium battery

-

Ultra-narrow lithium battery

-

Lithium battery models list

-

- ABOUT

- ONLINE FACTORY

- CASE

- NEWS

- FAQ

- CONTACT

401,Building A1,No.168,Changshan IndustrialZone Liulian Community,Pingdi Street,Shenzhen Guangdong Province,China

401,Building A1,No.168,Changshan IndustrialZone Liulian Community,Pingdi Street,Shenzhen Guangdong Province,China